Select Compton solar installers who are familiar with LA County permits, SCE interconnection, and NEC updates, and engineer for seismic, wind uplift, and marine corrosion. Expect a site survey, stamped structural/electrical plans, shade analysis, and racking with proper flashing and torque specs. Demand UL-listed equipment (UL 1741, UL 2703, UL 61730), rapid shutdown per 690.12, clear line-item pricing, and transferable warranties that cover roof penetrations. Get NEM 3.0 and ITC guidance, monitoring, and maintenance so your system stays safe, efficient, and compliant—additional specifics follow.

Key Takeaways

- Local expertise in Compton: LA County permitting, SCE utility interconnection, current NEC standards, seismic mounting systems, along with marine environment corrosion protection.

- Tailored engineered designs: roof structure review, solar shading analysis, seismic and wind uplift calculations, and visually appealing conduit/array planning.

- Quick, code-compliant installations: site evaluation 1-2 hours, permitting 1-3 weeks, average 1-2 day installation with NEC 690 and OSHA compliance.

- Premium, certified equipment: Tier-1 modules, UL/IEC certifications, UL 1741-compliant inverters, Class A fire rating, and components listed with CEC including monitoring.

- Comprehensive warranties and complete documentation: 25-year performance assurance, roof-penetration protection, transferable terms, and complete permit/PTO documentation and inspection checklists.

Why Local Knowledge Is Important in Compton

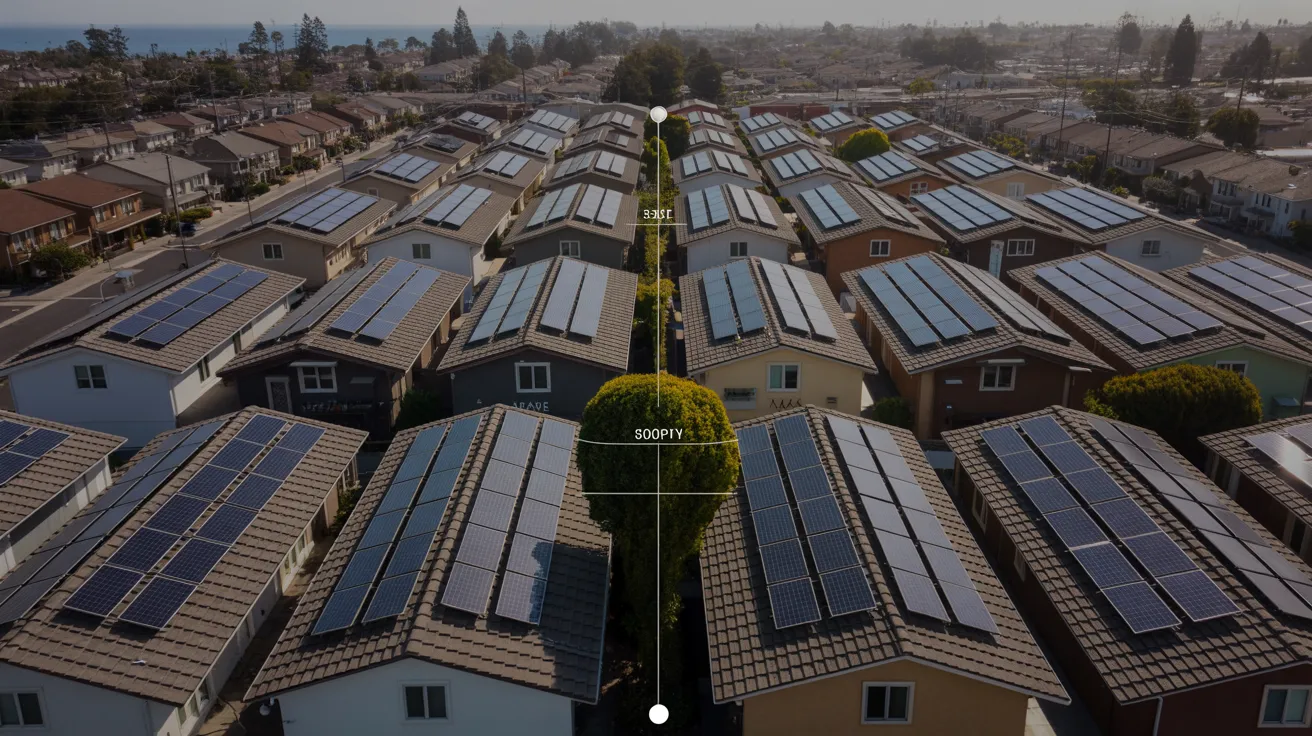

Because Compton sits in a dense urban heat island with coastal influence, local solar expertise makes certain your system is built to compliance and optimized for real conditions. You need installers who understand LA County permitting, NEC updates, SCE interconnection, and seismic anchoring. They'll select corrosion-resistant hardware for marine air, specify wind uplift ratings, and design for high roof temperatures that decrease module efficiency.

Neighborhood experts use local expertise to evaluate shading from mature trees, residential building offsets, and alley access for safe work zones. They coordinate primary electrical panel improvements, AFCI/GFCI protection, emergency shutdown features, and arc-fault mitigation. You'll receive accurate load calculations, balanced strings, and compliant grounding.

They further combine storage and smart inverters to provide Grid resilience, voltage ride-through, and export controls that avoid backfeed concerns.

Upfront Pricing & Financing Solutions

Using the same precision we bring to code compliance and safe engineering, we price systems with line-item clarity so you know exactly what you're paying for. You'll see every cost itemized—modules, inverters, racking, monitoring equipment, balance-of-system parts, labor, permits, interconnection, and inspections. Our upfront estimates meet NEC, utility, and city requirements, so there are no surprise change orders tied to safety or code.

We detail labor assumptions, conductor runs, roof attachments, and main-panel work before you sign. If your utility requires a meter upgrade or a rapid-shutdown device, we list and justify it. For financing, you can pick cash, flexible loans, or third-party options with transparent APRs and prepayment terms. We disclose incentives, timelines, and ownership implications, and we validate eligibility before applying credits.

Tailored Solar Systems Design for Compton Residential Roofs

From initial site survey through stamped plans, we engineer each Compton array to your roof's structure, orientation, and electrical service so it performs securely and passes initial inspection. We start with a roof assessment: age, decking type, rafter spacing, and load paths. Then we run shade analysis using hourly solar path data and nearby obstructions to size string configurations and select module layouts that satisfy production targets.

You get a racking specification that includes wind and seismic anchoring, rail spans, and uplift calculations appropriate for local conditions. We outline conductor sizing, OCPD, rapid shutdown, and grounding/bonding per NEC. We also plan aesthetic integration: color-matched hardware, conduit routing, and array symmetry that maintains sightlines. Finally, we verify inverter placement for proper ventilation, adequate service clearance, and safe access for working.

Permit Requirements, Inspections, and Code Compliance

You'll work through Compton's local permitting process, including plan sets, structural calculations, and electrical one-lines that satisfy city submittal requirements. We'll coordinate your system with current NEC, California Electrical Code, and local fire setback regulations so inspectors can verify grounding, overcurrent protection, labeling, and disconnects. You'll clear inspections promptly and securely by following documented standards and addressing any noted deficiencies promptly.

Municipal Permitting Procedures

Although each jurisdiction has nuances, Compton's solar permitting hinges on securing an electrical permit and, when necessary, a structural or building permit that demonstrates adherence to the California Electrical Code (CEC), California Building Code (CBC), and the City of Compton Municipal Code. You will need to submit stamped plans, a single-line diagram, load calculations, panel anchorage details, and UL listings for modules, inverters, racking, and rapid shutdown. Also include site plan setbacks and roof live/dead load verification.

Reach out early with the Building and Safety Division to verify submittal requirements, fees, and permit timelines. Leverage community outreach to anticipate HOA stipulations and neighborhood concerns. If your array exceeds structural thresholds, supply a licensed engineer's letter. For battery integration, provide ESS cut sheets and fault-current data. Pay online, track status, and reply promptly to plan-check comments.

Inspection and Code Standards

Once your permit is issued, inspections confirm that the installed system matches approved plans and complies with the California Electrical Code (CEC), California Building Code (CBC), and the City of Compton Municipal Code. You'll schedule preliminary and final inspections. Inspectors validate roof safety standards, including engineered attachment spacing, appropriate flashing, and penetrations sealed to preserve weatherproofing. They'll assess structural loading, setback clearances, and fire access routes.

Concerning electrical compliance, you can expect confirmation of conductor sizing, overcurrent protection, grounding and bonding, rapid shutdown labeling (CEC 690), and proper PV disconnect placement. Inspectors will review conduit support, wiring methods, and inverter/ESS certifications per UL requirements. You must supply access to roof arrays, labels according to NEC Article 690, and accurate as-builts. Address any notes promptly to obtain final approval and utility interconnection.

Premium Machinery and Warranty Coverage

You obtain Tier-1 panel brands verified for IEC/UL listings and bankability, guaranteeing stable output and tested safety. We outline inverter performance guarantees with documented efficiency, rapid-shutdown compliance (NEC 690.12), and surge protection that meets manufacturer requirements. You also obtain complete warranty terms- product, performance, labor, and roof-penetration- clearly defined with RMA procedures and transferability.

First-Tier Solar Panel Manufacturers

Your system's performance is anchored by Tier-1 solar panels with top-tier efficiency cells, robust module construction, and credible manufacturers that fulfill rigorous IEC/UL certifications. You get High efficiency modules built for reduced degradation, PID resistance, and superior temperature coefficients, which maintain output in Compton's heat. Manufacturer reliability is crucial: opt for brands with integrated manufacturing processes, audited quality control, and BloombergNEF Tier-1 bankability. Look for UL 61730/IEC 61215 and 61730 listings, fire class A ratings, and California CEC listings to make certain code compliance.

Choose modules with 25-30 year linear performance warranties and a minimum of 12-25 year product warranties, reinforced with U.S.-based service channels and strong balance sheets. Designate sturdy frame designs, reinforced glass, and certified load ratings for wind and seismic zones. Appropriately matched connectors and listed rapid-shutdown compatibility protect installations and preserve warranty coverage.

Inverter Performance Assurances

After selecting high-spec modules, match them with premium inverters that feature explicit performance guarantees and extensive warranties suited to Compton's climate and code. You should require manufacturer-backed performance metrics that outline minimum CEC efficiency, MPPT voltage windows, and permitted efficiency degradation over time. Ensure warranty alignment with NEC Article 690, UL 1741 SA/IEEE 1547 compliance, and utility interconnection requirements. Require documented inverter longevity tested under elevated temperature and marine corrosion conditions typical of South LA.

Define guarantees for annual uptime, MTBF, and rapid shutdown interoperability per 690.12. Demand replacement or repaired-in-field commitments within defined response times, and coverage for labor during RMA. Verify monitoring accuracy (±1% energy metering) and data retention. Assure surge protection ratings and thermal derating curves are disclosed so you can model lifecycle output and safety margins accurately.

Comprehensive Guarantee Requirements

Begin by requiring bundled, written warranties that cover solar panels, inverters, mounting systems, balance-of-system parts, and labor, each aligned with specific code and utility requirements. Demand UL/IEEE listings, NEC compliance language, and proof the installer's labor warranty aligns with California C-46 scope. Specify product terms: 25-year module performance, 10-25-year inverter coverage (with rapid-shutdown electronics), and corrosion-rated racking. Verify roof penetration warranties match roofing manufacturer standards and include leak remediation.

Check warranty transferability for home sales without fees or reduced terms. Demand clear exclusions (electrical surge, vermin, saline corrosion) and site conditions. Demand a documented claims process with response SLAs, parts logistics, and authorized labor rates. Demand bankruptcy-backed assurances (escrow protection, insurer-backed warranties) and owner-accessible serial registration. Maintain all documents tied to permit numbers and PTO records.

Timeline for Installation and What to Anticipate

Even though every project is distinct, you can count on a straightforward, code-compliant timeline: site evaluation and load calculation (1 to 2 hours), engineered design and permitting (one to three weeks contingent upon AHJ), installation day or days with OSHA-compliant fall protection and lockout/tagout for electrical work (one to two days for conventional 5-10 kW systems), utility and building inspections (two to seven days), then PTO (permission to operate) from your utility (1-2 weeks).

In the site evaluation, we verify structural members, main service rating, grounding/bonding paths, and conduit routes. We perform roof prep, including rafter mapping, flashing layout, and attachment torque checks per manufacturer specs. A crew briefing covers hazard controls, staging, and NEC/CEC compliance. Installers mount racking, run PV circuits, set the inverter, and label per Article 690. You can expect prompt inspections, corrections if necessary, and a final walkthrough confirming system operation, shutoff locations, and documentation.

Monitoring, Maintenance, and Ongoing Support

Routinely track system performance through your monitoring portal, which we configure to display string- or module-level data, inverter status, production versus consumption, and NEC 690.12 rapid-shutdown readiness. You will receive alerts for ground faults, arc-fault events, abnormal voltages, and communication losses, permitting rapid, code-compliant responses.

We support remote diagnostics to analyze device logs, IV curves, and temperature data, so we can pinpoint issues without delay. Our maintenance plan includes preventive maintenance based on trend analysis: cleaning schedules derived from soiling index, torque checks at racking attachment points, and infrared scans to locate hotspots before failure. We also check labeling, disconnect operations, and breaker ratings per NEC and utility interconnection requirements. When onsite service's required, technicians follow LOTO, fall protection, and manufacturer procedures.

Boosting Savings With Financial Programs and Net Metering

While system design establishes baseline economics, you enhance ROI by combining incentives and optimizing net energy metering under current California rules. Implement incentive stacking: claim the federal Investment Tax Credit, pair eligible energy storage, and pursue utility or state rebates if eligible. Validate eligibility, safe interconnection, and labeling per NEC, UL listings, and utility tariffs.

With NEM 3.0, export tariffs track hourly avoided-cost values, so you should dimension arrays and batteries to maximize self-consumption and move exports to high-value timeframes. Configure batteries for time-based arbitrage and critical load protection, preserving required disconnects, rapid-shutdown devices, and commissioning records. Validate meter aggregation, solar-access rights, and AHJ permits. Review interconnection agreements, non-bypassable charges, and true-up schedules to prevent bill surprises and protect long-term savings.

Client Reviews and Case Studies in Your Community

You can confirm performance by reviewing neighborhood case examples that list system size, module specs, code compliance (CEC, National Electrical Code), and inspection results. Review local homeowner success stories that document interconnection timelines, net-metering outcomes, and production vs. utility bills with measured kWh. Give priority to projects with permitted designs, licensed installers, and clear safety records, including Authority Having Jurisdiction approvals and final sign-offs.

Local Project Success Stories

Dig into actual data from Compton residents to discover how code-compliant design, safe installations, and documented performance measure up across roof types and electrical setups. You can review 3 kW to 8 kW systems on tile, shingle, and flat roofs, each with electrical load calculations, AHJ permits, and NEC 690-compliant wiring. Assess inverter uptime, rapid-shutdown verification, and output versus PVWatts forecasts. Discover how main-panel upgrades, line-side taps, or derates secure breakers and conductors.

You'll discover block parties that showcased array layouts, conduit routing, and labeling, plus community grants that cover costs for lower-income homes. Verify shade-mitigation with optimizers, wind uplift anchoring per manufacturer ESR, and water-tight flashing. Confirm grounding, bonding, and GFCI protection. Utilize these highlights to benchmark durable, safe performance.

Stories of Success from Local Homeowners

From the first property evaluation to PTO, Compton homeowners report code-compliant system installations that perform as modeled and pass inspections on the first try. You'll observe reliable outcomes: get more info National Electrical Code-compliant conductor sizing, properly labeled disconnects, securely bonded racking, and flush installations that fulfill setback and wind uplift standards. Installation crews validate roof structure, seal penetrations with properly flashed attachments, and submit accurate as-builts, so inspectors provide sign-off without modifications.

Residents share measurable findings at local workshops and community sessions: shade evaluation met production forecasts within 2-4%, rapid-shutdown devices tested at commissioning, and inverter programming refreshed for Rule 21 and UL 1741 SA. You'll appreciate well-prepared utility interconnection packages, AFCI verification, and ESS clearances. Post-installation tracking demonstrates stable output, and maintenance protocols preserve equipment within manufacturer specs.

How to Pick the Ideal Compton Solar Installer

Prior to contract signing, assess Compton solar installers based on licensing, experience, code compliance, and safety practices. Confirm state contractor licenses, CSLB status, and insurance. Request installer certifications (for example NABCEP) and OSHA training. Ensure they handle solar permits with the City of Compton, interconnection applications with SCE, and Title 24/CEC requirements. Evaluate their NEC 690/705 knowledge, rapid shutdown compliance, grounding/bonding methods, and labeling.

Obtain engineering drawings, structural analysis for roof loads, and product data sheets. Check inverter, racking, and module compliance standards (UL 1741, UL 2703, UL 61730). Evaluate workmanship warranties, monitoring setup, and O&M response times. Inspect references and latest projects. Compare proposals on system size, production modeling, equipment specifications, and price per watt. Opt for transparent communication, documented processes, and clear safety standards.

Questions & Answers

Do You Offer Battery Storage and Whole-House Backup Solutions?

You can obtain battery storage and whole-home backup solutions. We assess critical loads, panel capacity, and service upgrades, then determine battery backup systems with UL-listed equipment and NEC-compliant wiring. We perform backup sizing to achieve outage duration goals and code-required load calculations. You'll select full-home or critical-circuit backup, with integrated transfer switching, rapid shutdown, and surge protection. We take care of permitting, utility interconnection, and commissioning to ensure safe, reliable operation.

Can EV Chargers Be Integrated With the Solar System?

Yes, you can integrate EV chargers with solar installations. We engineer EV integration to focus on solar generation, facilitate smart charging schedules, and satisfy NEC, UL, and local permitting codes. You'll obtain load calculations, panel upgrades if required, and dedicated circuits with GFCI/AFCI protection. We accommodate Level 2 chargers, OCPP networking, and utility demand response solutions. We also program backup behavior with batteries, eliminate backfeed, and verify commissioning with inspection-grade test results.

How Do You Manage HOA Requirements and Aesthetic Standards?

You handle HOA approvals by initiating design consultations that convert covenants into compliant layouts and equipment requirements. You present detailed plan sets, elevations, and color-matched options, then coordinate permit coordination to align HOA guidelines with local code and utility interconnection. We offer low-profile racking, concealed conduit, and flush mounts to meet aesthetic specifications. You document setbacks, fire pathways, wind/snow ratings, and bonding/grounding to ensure safety, code compliance, and smooth approval timelines.

What Takes Place if I Move-Is the Solar Agreement Transferable?

Certainly-you have the option to transfer the solar agreement upon moving. The majority of providers present straightforward transfer alternatives through a structured contract transfer to the purchaser, subject to credit review and utility interconnection compliance. You should alert the provider ahead of time, furnish system information, and coordinate inspections to meet NEC and local code requirements. Should the purchaser refuse, various agreements offer prepayment or buyout alternatives. Document everything to maintain warranties and safe, code-compliant operation.

Do You Provide Options for Solar on Multifamily or Rental Properties?

Indeed. You can install solar on multifamily and rental properties with code-compliant designs. We evaluate roof structure, fire setbacks, and service-entrance capacity, then configure dedicated arrays, smart inverters, and rental metering via virtual or physical submetering. You'll utilize multifamily incentives, including virtual net metering and low-income adders where eligible. We prepare interconnection single-line diagrams, obtain permits, and implement rapid shutdown, labeled disconnects, grounding, and monitoring to provide safe, reliable operation.

Final copyright

You're ready to turn high bills into a milder monthly whisper. With a local, code-compliant installer, you'll get precise load calculations, NEC-aligned wiring, and AHJ-approved permits without any surprises. Your roof gets a custom array, premium UL-listed hardware, and warranties that remain solid. You'll monitor performance, keep maintenance organized, and claim incentives and net metering to ease costs. Check neighborhood reviews, compare transparent proposals, and choose the team that treats safety as non-negotiable—and savings as your new normal.